BAG OM PRODUKTIONEN

BAG OM PRODUKTIONEN

Lys efter stolte håndværkstraditioner

Vi har produceret levende lys siden 1965. Det betyder, at vi laver lys med afsæt i mere end 50 års erfaring, traditioner og med et skarpt blik for hvert led i produktionen.

Resultatet er levende lys i en kvalitetsklasse for sig med en lang, smuk og jævn afbrænding. Det er vi stolte af – faktisk så stolte at vi elsker når vores kunder er på besøg på fabrikken.

Det er dog ikke alle, der har mulighed for at kigge forbi Hasselager. Derfor kan du på denne side læse mere om, hvordan vi laver vores lys.

Kvalitet starter ved de gode råvarer

Derfor bruger vi kun det bedste på markedet.

Vi har nøje udvalgt de bedste råvareleverandører i Europa, der alle er udmærkede ved at være certificerede RAL GZ 041 leverandører. Alle vores lys består således af 100% fødevareforberedt paraffin.

Vores væger er tilpasset det enkelte lys for at sikre, at lyset brænder optimalt

I bestræbelserne på at lave lys, der brænder perfekt og sod-frit, er detaljer helt ned til de enkelte tråde i vægerne vigtige, og vi har derfor udvalgt de bedste væger fra den tyske producent, Henschke Docht. Fælles for alle vores væger er, at de lever op til den strenge Oeko-tex 100 standard. Det garanterer blandt andet, at vægerne ikke indeholder bly, og dermed ikke udleder bly ved afbrænding.

Fordi vi udelukkende arbejder med paraffin, kan vi bruge bomuldsvæger, der ikke er imprægneret med f.eks. salt. Det mindsker partikeludledningen gevaldigt – faktisk i en sådan grad at der praktisk talt ikke er ultrafine partikler i luften, når du afbrænder et paraffinlys.

Selvfølgelig forudsat, at det brændes korrekt.

2 lystyper – 2000 variationer

Hos Diederich Lys har vi specialiseret os indenfor to lystyper: Bloklys og dyppelys. De kommer i forskellige tykkelser og længder og kombineret med vores 50+ farver og forskellige typer finish (lakeret, børstet eller med print), har vi over 2000 unikke lys i vores sortiment.Bloklys

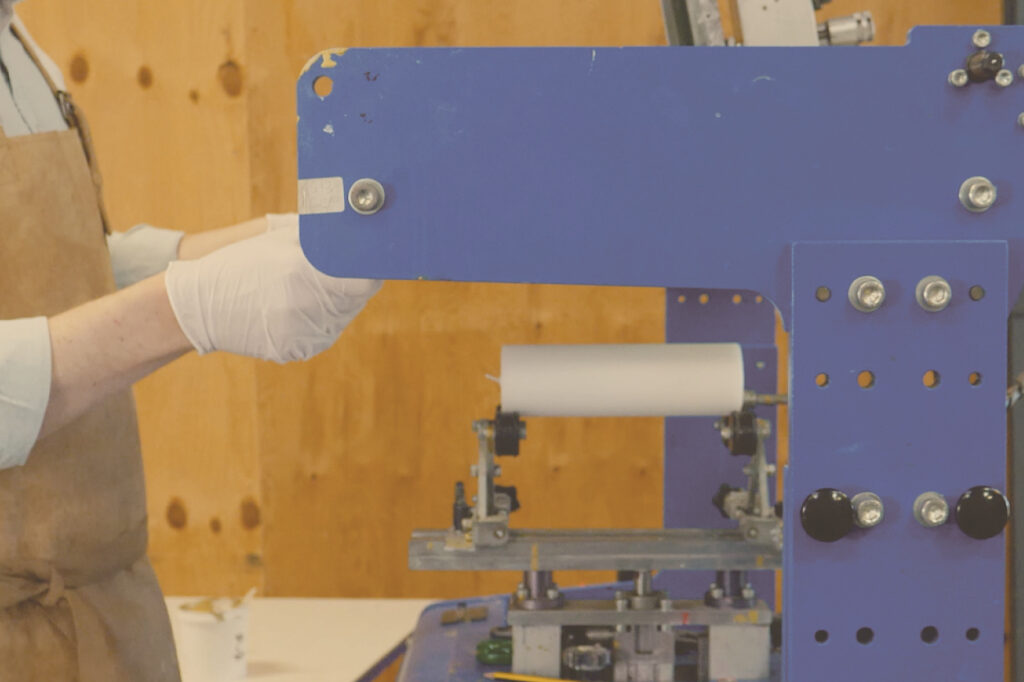

Vores bloklys fremstilles via en metode, som kaldes “koldkomprimering”. Det betyder, at paraffin-granulat presses sammen om vægen under et tryk på op til 2 ton. Denne meget hårde komprimering gør, at brændetiden på lyset forlænges.Dyppelys

Vore dyppelys produceres, som navnet fortæller, ved at vægen dyppes i flydende paraffin, som er ca. 65 grader varm.Farvning

Alle vores lys har en kerne, som består af 100% fødevareforberedt paraffin. Vores lys er derfor kun farvet i overfladen, og det skyldes primært, at gennemfarvede lys soder mere.

Vi har egentligt maskinerne til det – men vi foretrækker altså at farve vores lys i hånden. Med en stor portion kærlighed dypper vores dygtige medarbejdere lysene i en farvet voks, som har et andet smeltepunkt end kernen.

Det betyder, at kernen smelter lidt hurtigere end overfladefarven. Derfor brænder lyset utroligt jævnt og smukt, og du vil med et Diederich Lys ikke opleve, at det yderste lag revner og lysene dermed løber.